IMC Scribe Marking Machine

| Project Scope: CMT to supply a stand alone Diamond Scribe marking machine to mark a high resolution Square Dot 2D Matrix with man-readable text and non-printing ASCII characters (additional mark security) onto automotive racing parts. Materials are steel and aluminum. Machine is manual load / unload. Marking times vary from 20 seconds to 2 minutes depending on the part.

CMT to provide: Options: a) Replacement pin |

|

Picture of marked part

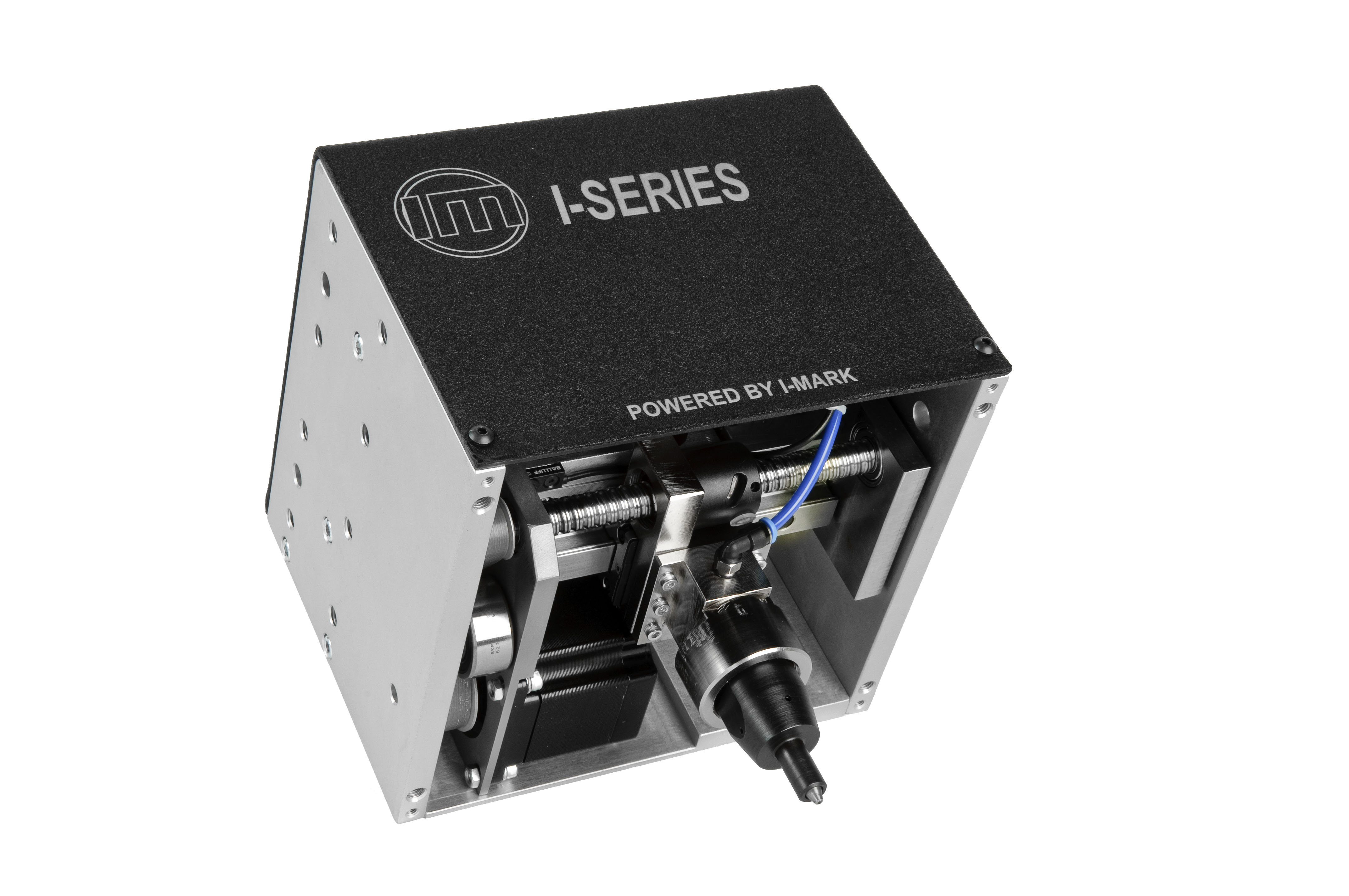

IM-C150-ST-AS-00-00 – I-Mark programmable scribe unit includes all required components for setting up a marking station:

* Controller Series-200 (Upgrade)

* I-Mark PC software (Customer supplied PC required for initial programming, and may be used for monitoring over Ethernet)

* Cable to connect Marking Head to Controller, 10 ft

* Crossover cable to connect controller to PC (not required if connected directly to internet)

* Requires 1 shop air line 1/4″ NPT and 110VAC power supply

Marking Head Assembly

* Marking window 100mm x 150mm (4″ x 6″)

* Marking stylus speed of 2-3 characters per second

* Stepper drive system with linear machine way and protective bellows

* Ballscrew driven X & Y axis

* Narrow head design

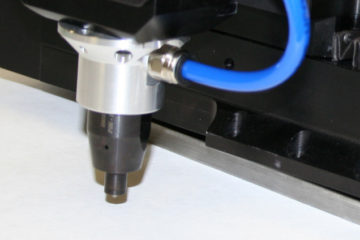

* All metal pin assembly

* Uses diamond stylus

* Extreme quality construction; designed for harsh environments

CONTROLLER Series-200 (Upgrade) including:

* NEMA 4 industrial enclosure 16″ W x 12″ H x 8″ D

* I-Mark networkable motor drive for stepper motor control

* Sixteen (16) 24vdc optically isolated digital I/O fully programmable with software for controlling external hardware devices to help save costs in automated applications. (8 inputs and 8 outputs)

* Binary select feature for selecting & executing multiple programs via the I/O

* Ethernet 10/100 BaseT communications for programming and integration into system network (can be used with static IP setup or in DHCP mode on a network)

* Modbus TCP protocol for streaming data input (other protocols optional)

* I-Mark high resolution networkable motor drives for stepper or servo motor control with 10a peak motor output per axis. (Up to 4-axis per controller)

* Binary select feature for selecting & executing multiple programs via I/O.

* Digital current and servo loops with line driver encoder for controlling servo motors

* Closed or open loop stepper motor control with micro stepping capability.

* Industrial Harting interface connectors for marking head & I/O

* Manual reset / E-stop pushbuttons. (also featured as remote options in the I/O interface)

* Series 200 Upgrade to Operator touchscreen station including:

– Remote touchscreen color display to aid programming

– Designed for use with standard benchtop stand

– I-Mark software preloaded and resident on control, includes intergated PC with USB ports

– Onscreen virtual keyboard

– Backup keyboard with integrated mouse