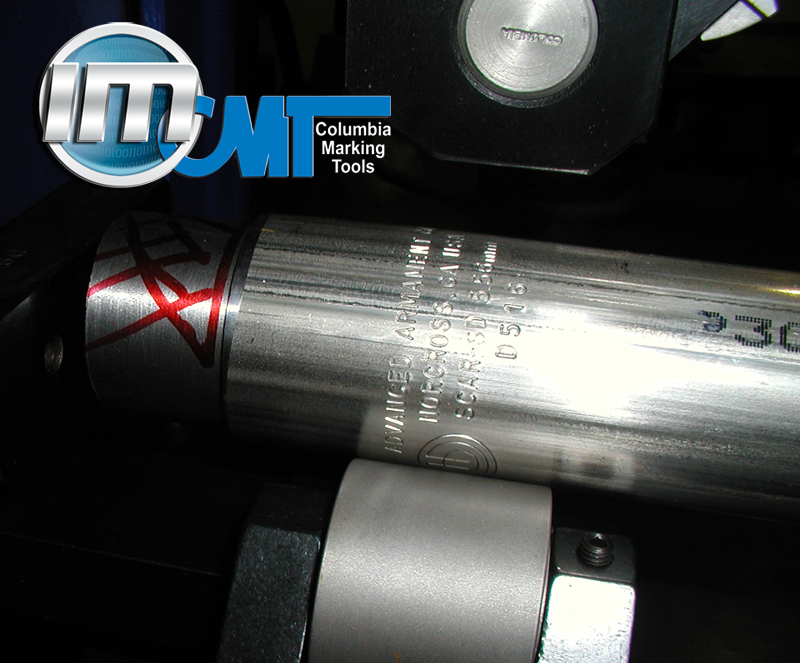

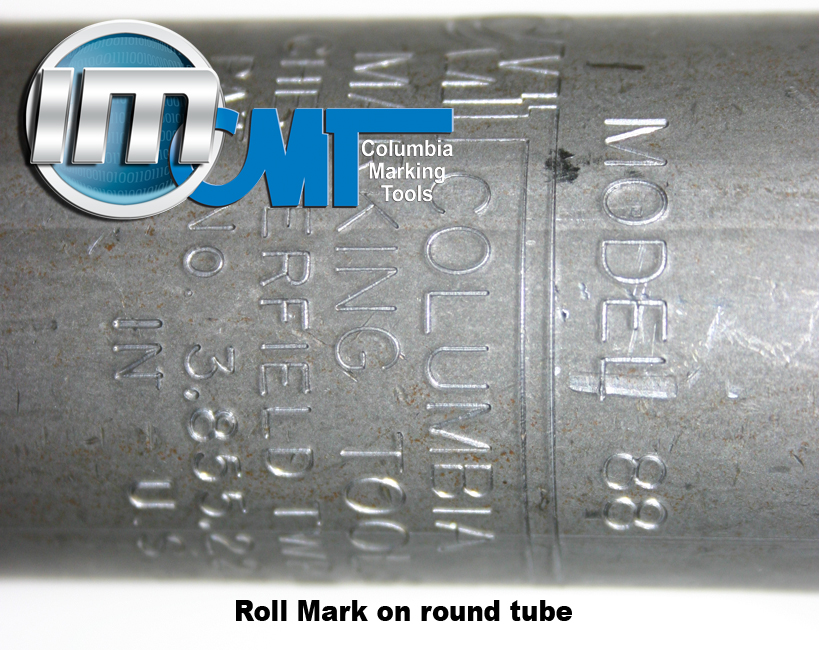

Case Study: Roll Marking Exhaust Tubes

Overview:

This case study highlights the use of Columbia Marking Tools’ Model 860 all-air roll marking machine to mark 3 1/4″ steel exhaust tubes in an automotive application. The goal was to achieve precise and consistent part identification while maintaining efficiency in a high-production environment.

Project Details:

Part: 3 1/4″ exhaust tube (automotive)

Material: Steel

Character Size: 1/4″

Number of Characters: 9

Marking Method: Roll Marking

Machine Used: Model 860 All-Air Roll Marking Machine with A43 Cylinder (4300 lb)

Air Pressure: 80 psi

Cycle Time: 2 seconds

Challenges:

Ensuring consistent and deep marking on curved steel surfaces.

Maintaining fast cycle times to meet production demands.

Utilizing a fully pneumatic system for efficient operation.

Solution:

The Model 860 all-air roll marking machine was selected due to its ability to apply uniform and durable marks on cylindrical steel parts. The machine’s A43 cylinder, delivering 4,300 pounds of force, ensured deep and clear impressions, even on hardened steel surfaces. By operating at 80 psi air pressure, the system maintained a rapid cycle time of just 2 seconds, significantly improving production throughput.

Results:

Clear and durable markings that meet industry specifications.

Increased efficiency with a two-second marking cycle.

Reliable and repeatable performance with an all-air system, reducing maintenance costs.

Conclusion:

The implementation of Columbia Marking Tools’ Model 860 roll marking machine provided a robust and efficient solution for marking steel exhaust tubes in a high-volume automotive production setting. Its powerful pneumatic operation and rapid cycle time ensured consistent, high-quality marks while maximizing operational efficiency.