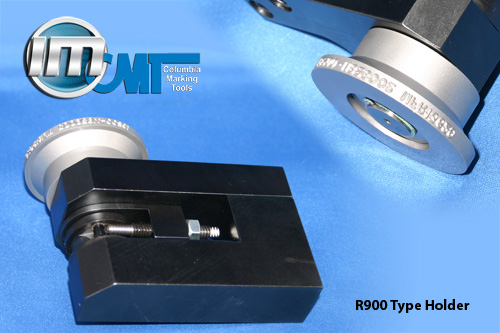

R900-R800 Operation Guide

Instructions for setting up CMT-CNC Lathe roll marking attachment

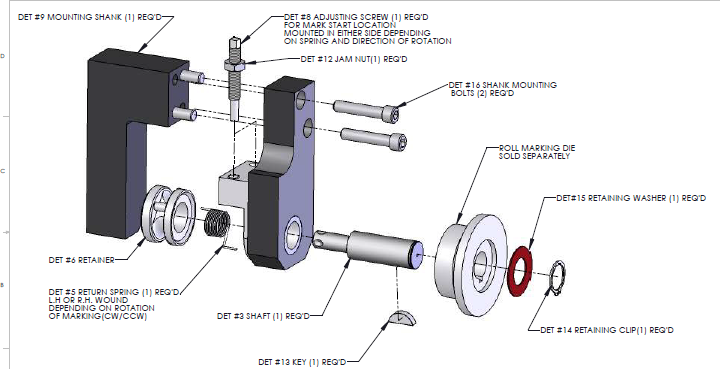

Mount the holder into the acceptable tool holder (WITHOUT THE WORK ROTATING). The lathe slide is brought in so that the cam rise of the marking roll touches the work. (WORK MUST NOT ROTATE) Apply enough pressure to indent the mark between .002 and .004 (cam rise of the roll against the

work) back tool away, start machine, and bring holder and roll in contact with the work. At this point, the cam on the roller should engage against the work, causing the roll to rotate and imprint the work. If the mark made by the roller is too shallow, push the arbor shaft out only far enough to the

splines. Rotate the roll one or two notches in the direction that will cause the cam to contact the work closer to the beginning of the cam rise. (Depth of impression will change. It is necessary to go through the first procedure again, for now there will not be enough pressure between the work and

cam to start roll rotating or so much pressure it may cause roll to jam or slip, depending upon which way you rotate).

If the impression is too deep, rotate the roll in a direction that will cause the cam to turn toward the work, thereby making the roll contact the work closer to the engraved lettering.

General – The closer to the cam you start to the lettering, the less pressure you will exert between the roll and the piece you are marking, the shallower the impression depth. The closer to the beginning of the cam you start, further from the lettering, the more pressure you exert between the

roll and the piece you are marking, therefore giving you a deeper impression.

On CNC lathes often the tool to part distance is programmable and thus should be treated like a typical knurl or other lathe tool. The slowest speed is recommended however many operators increase speed as they become more familiar with the tool and material they are marking.

The shaft of the roller should be on the same center-line as the work or as much as 1/64″ below the center, but this is maximum.