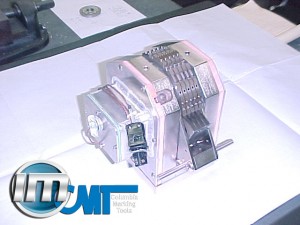

Numbering Head 123H-5A-1/2″ W3834

123H-5A-1/2″ W3834- Hot stamp automatic numbering head featuring:

a) Total stamping width 1.404″ -.206″w x .500″high characters with .093″ between each per sketch

SK-100

b) Five wheel automatic actuation, auto/manual indexing, w/auto indexing pawl mounted on back of head

(away from operator), and easily disengaged for manual operation

c) Auto index pawl to be made of hardened tool steel. Actuating yoke to be hardened tool steel, plated

and have cross hole for actuation disengagement

d) Adequate hand clearance for manual indexing; to be accomplished by mounting retaining fingers and

comb spring assembly above wheels, between wheels and frame

e) Heavy duty cast iron plated frame

f) AMPCO bronze main shaft

g) Frame to be centered on mounting plate left to right and shaft to be centered on mounting plate front to

back

h) Insulation on both sides of frame

i) All wheels solid, AMPCO bronze, with removable zeros

j) Each wheel to have 1/8″ dia x 3/8″ deep indexing holes between every number for manual advance

k) Use reverse print, units wheel to be on left hand side looking at the front (operator’s side) of the head

l) Use .100″ deep engraving; flat face, no cross hatch, deburr edges (soft edge)

m) Engraving masters to be supplied by Y-TEX

n) Heaters to have swaged in, flexible high temperature leads, and a non-stick coating

o) Thermocouple to be an Ogden T130 ring type or equal, surface mount, located near the bottom of the

frame. Drill and tap for Ogden type 221 well

Tolerances

i) Wheel to wheel character stamping surface not to exceed .003″ total

ii) Wheel to wheel character alignment not to exceed .005″ total

iii) Maximum allowable character movement is .002″ in all three dimensions whether in auto or manual

indexing mode

iv) Characters in stamping position must be parallel to mounting plate – within .001″

v) Operating temperature 450 -600 degree F