Laser Marking – TOOLING Automation

- Figure 1

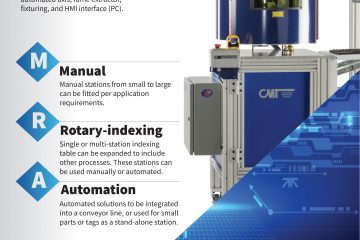

- Figure 2

- Figure 3

Laser Marking – TOOLING Automation

As each part of the manufacturing process is viewed in detail for additional costs savings, tooling goes under a microscope. While some companies focus on the cost of the tooling, others focus on the amount of changeover time and longevity. A compressor manufacturer was looking to purchase a marking laser and required the system to mark two distinct parts- compressor housings that were two different sizes and materials. In addition, they were required to be marked on two sides, 90 degrees from each other. The manufacturer was looking for a single system that would require no tooling changeover, or selector switches.

Columbia Marking Tools has designed and built many custom designed marking stations, and has added laser marking to meet the challenges and requirements of the industrial manufacturers. In this case, Columbia Marking Tools was able to provide a custom CMT Pro-Mark Pulsed Fiber Station with fully automated tooling as shown in figure 1. The operator manually scans a bar code label prior to loading the part into the machine. Once the part is placed in the part pallet the operator initiates the marking process by touching the palm buttons. At that point the operator’s job is complete until the part is ready for unloading. The pallet drawer closes automatically; the drawer itself provides the guarding for the Class 1 laser enclosure. Part sensors are used to determine which of the two models are being marked. Once this is determined the laser head is positioned automatically in the correct position. No manual adjustment of any tooling is required to change from model to model. The laser head moves from clear to mark location and has (2) marking positions – horizontal and vertical. In addition, these two mark locations will achieve proper laser focal distance when locked into position.

The custom workstation houses a 20 watt pulsed fiber laser. This laser has a 1064 mm wave length pulsed Ytterbium source. This source is fitted with a 160mm F-Theta focusing lens. The available marking window is 4” diameter. The enclosure is a Class 1 laser enclosure with an integrated cycle interrupt safety switch. The system is a floor model with a heavy duty machine base and casters. A PC controller, which is attached to the side of the station, has a 15” touch-screen preloaded with all the proprietary laser software. The GUI operator interface includes a red diode tracing feature.

Once the laser completes marking the part model numbers and serial number, the pallet drawer automatically opens for unloading by the operator. This complete process is less than 30 seconds. The innovation in this case was not the speed of the mark, but the automation of the tooling and ultimately the time and cost savings to the manufacturer in having one marking station built to mark two different compressor housings.

About Columbia Marking Tools

Columbia Marking Tools is a leading designer and manufacturer of metal and plastic marking equipment including stamps, roll marking dies, roll marking and impact marking machines, fully programmable laser, peen/scribe marking and UID/2D Square – Dot® machines, numbering heads and special marking machines. For more information, visit www.columbiamt.com.