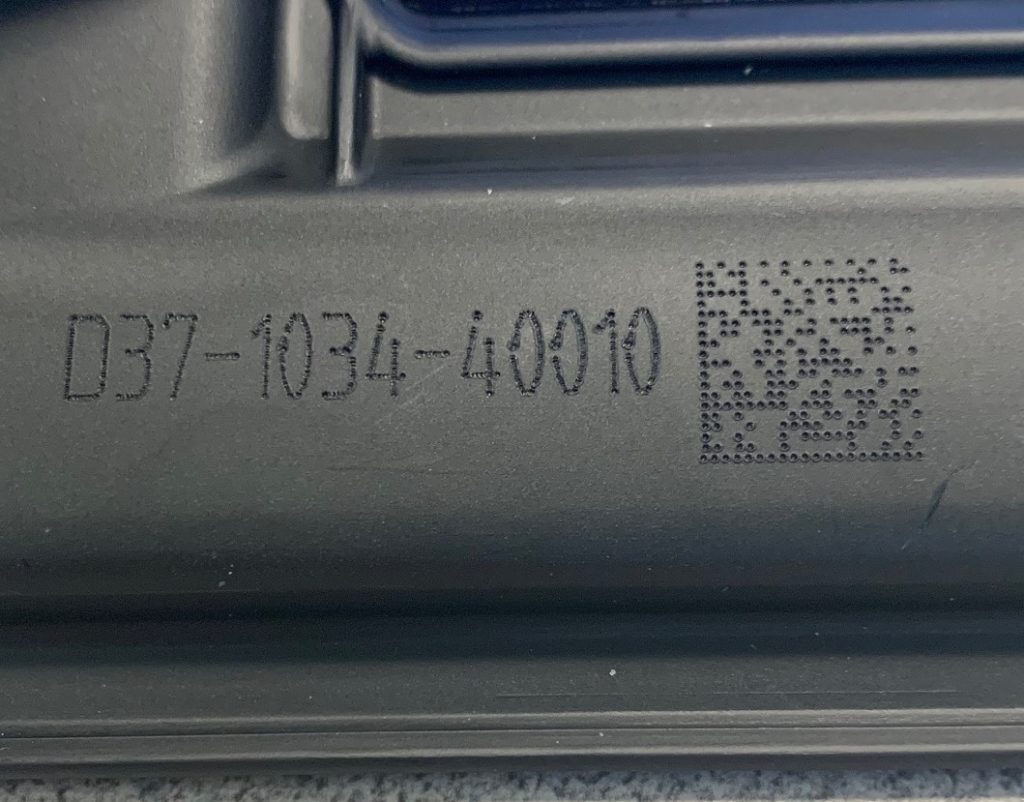

I-Mark Dot-Peen Mark on Plastic Part

Trace-ability is now a part of every production process. Even the plastic components of equipment need to be marked with date codes, part numbers, and product details.

The most common plastic marking techniques include: a) Marking in the dies with integrated steel stamps b) Hot stamping as a secondary marking process.

What a dot-peen marking solution can provide to high production marking is:

- Flexibility of the mark

- Reduction of marking legend changeover errors

- Integration with MES system or other digital input

- 2D codes for machine readable legends

- Light pressure on the part

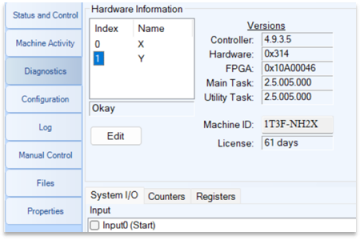

- Marking Solution tested: ID60

- Part Description: Filtration housing component

- Part Material: Glass filled nylon

- Mark info: Character size: 5MM

- Mark cycle time required: less than 10 seconds – 8.7 seconds as tested

- Mark info: # of characters: 14

- Character Size: 3/16″

- Air pressure: 30 PSI

The Dot-peen mark is clear and easily readable. These I-Mark Dot-Peen systems are designed for industrial high production marking.