I-Mark IM-M200 Bench Top Dot Peen Programmable marking system

IM-M200– I-Mark programmable dot peen unit includes all required components for setting up a marking station:

Marking Head Assembly

- Bench-top stand

- Controller Model 200

- Integrated PC, includes I-Mark software preloaded on Windows 7 (32 bit and 64 bit) platform

- Cable to connect Marking Head to Controller

- Monitor & Keyboard with integrated mouse

- Requires 1 shop air line 1/4″ NPT and 110VAC power supply

Marking Head Assembly

- Marking window 200mm x 200mm, 8″ x 8″

- Marks 3-4 Characters per second

- High quality linear shaft guides

- All metal pin assembly

- Uses carbide stylus

Bench-top Stand

- Quality Extruded Aluminum Base

- T-Slot table 12” x 14”

- Manual up & down movement column assembly with high quality lead screw

- Marks parts up to 11” tall

- System pressure regulator with air gauge included

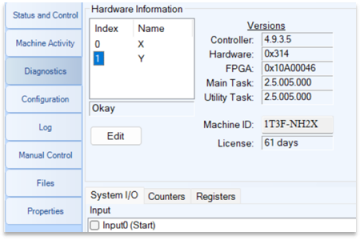

Controller Model 200

- NEMA industrial enclosure 14″ W x 8″ H x 6″ D

- Sixteen (16) 24vdc optically isolated digital I/O fully programmable with software for controlling external hardware devices to help save costs in automated applications. (8 inputs and 8 outputs)

- Binary select feature for selecting & executing up to 32 multiple programs via the I/O

- Ethernet 10/100 BaseT communications for programming and integration into system network (can be used with static IP setup or in DHCP mode on a network)

- I-Mark high resolution networkable motor drives for stepper or servo motor control with 10a peak motor output per axis. (Up to 4-axis per controller)

- Digital current and servo loops with line driver encoder for controlling servo motors

- Closed or open loop stepper motor control with micro stepping capability.

- Industrial Harting interface connectors for marking head & I/O

- Serial Data port for input

I-MARK Software including:

- Intuitive graphical user interface for mark layout / program creation.

- Drag and Drop functionality for easy program creation and entity sizing.

- Generate fixed or dynamic text entities. Including dates, times, counters, serial numbers, text placeholders, shift codes or Ascii characters.

- Dynamically adjustable character height, width, and separation features

- Multiple font support including OCR

- Advanced 2d data matrix code printing with built in depth/position control tools

- CMT patented SquareDot™ option for 2d matrix code printing on cast or other hard to read surfaces

- Programmable user way points and digital I/O within the marking sequence for creation of fully automated workstations.

- Import DWG/DXF drawing files for background imaging or graphical printing.

- Advanced axis jogging with position feedback for part setup and mark position teaching. Also includes printing simulator for testing mark position before printing

- Advanced fault and production data logging locally

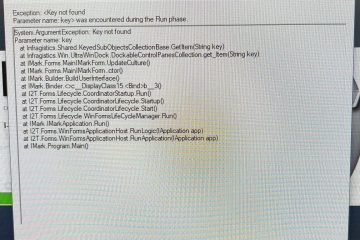

- Machine controller page with advanced diagnostics