Case Study: Air Scribe Bearing

Overview:

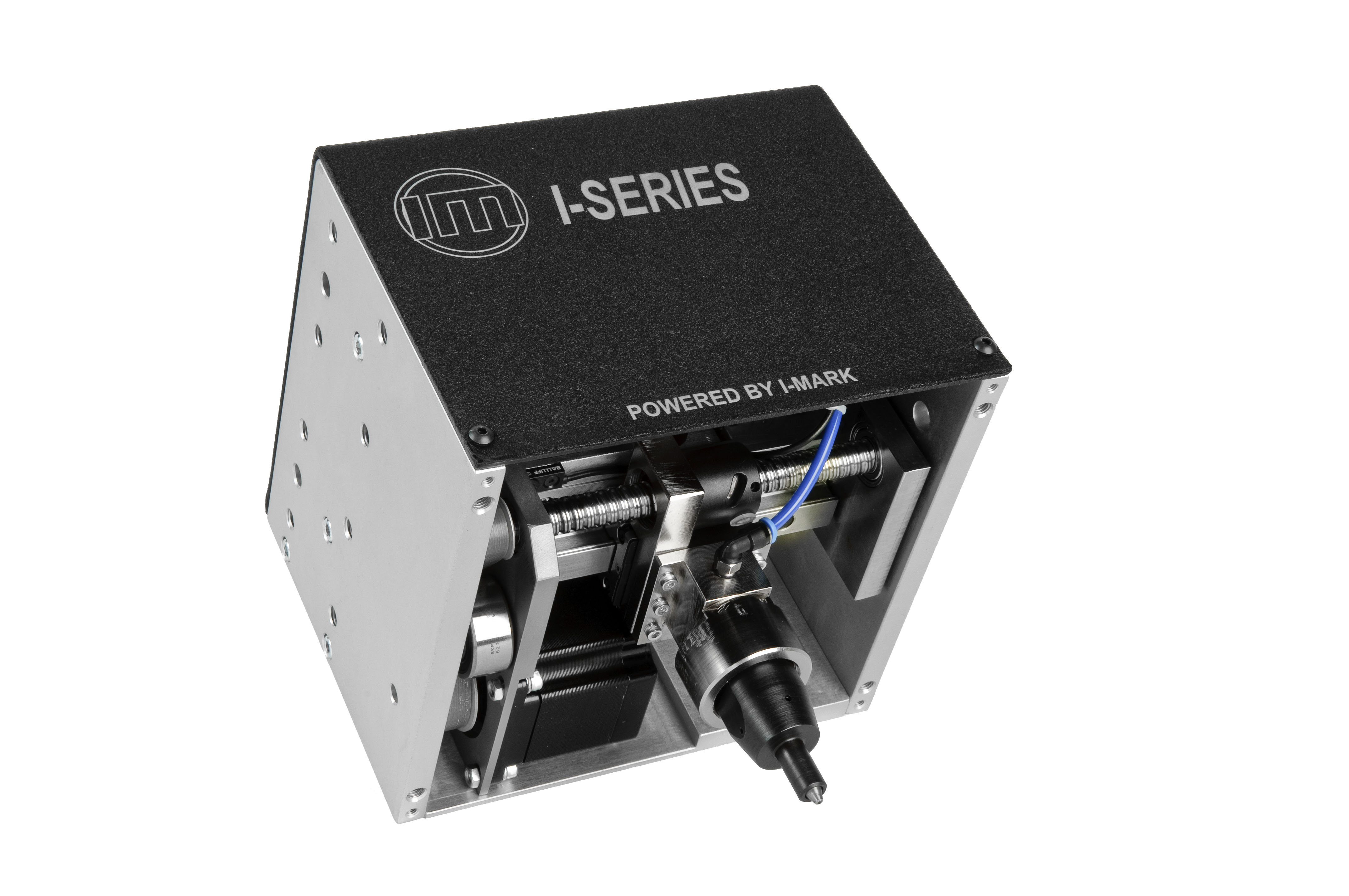

This case study highlights the use of the IM-C air scribe stepper for marking hard steel parts. The objective was to achieve precise, durable circular text markings while ensuring a cost-effective solution compared to laser marking. The system utilizes a ball screw drive with high-torque stepper motors and a diamond scribe for clear and permanent markings.

Project Details:

Part: Bearing 42Rc

Material: Steel

Character Size: 1/8″

Number of Characters: Circular Text

Marking Method: Air Scribe

Machine Used: IM-C Air Scribe Stepper

Air Pressure: 60 psi

Technology Used: Ball screw drive with high-torque stepper motors, diamond scribe

Challenges:

Ensuring high-precision circular text markings on hardened steel.

Providing a cost-effective alternative to laser marking.

Maintaining efficiency and repeatability in a high-production environment.

Solution:

The IM-C air scribe stepper, equipped with a ball screw drive and high-torque stepper motors, was selected for its capability to deliver controlled and precise circular text markings. The use of a diamond scribe ensured deep, clear, and durable marks on the 42Rc hardened steel surface, offering a cost-effective alternative to laser marking.

Results:

Highly legible and permanent circular text markings.

No compromise to the structural integrity of the bearing.

Increased efficiency with precision-controlled air scribe technology.

Significant cost savings compared to laser marking solutions.

Conclusion:

The implementation of the IM-C air scribe stepper for bearing marking provided a reliable and cost-effective solution for achieving high-precision identification. The combination of advanced stepper motor technology and diamond scribe marking ensures clear, durable, and industry-compliant part identification.