Handy Andy X – upgrades in Dot-peen marking

Handy Andy X Features wide Ranging Advances to this Popular Low Volume Part Marking Product

Just hook the system up to a PC, load the software, connect an air line and it’s ready to go.

CMT’s two-axis programmable dot-peen marking machine, the Handy Andy has become a favorite for low volume industrial manufacturers who require part marking. It is also used in tool rooms in large production facilities to mark fixtures and tooling. With an air-powered carbide bit, the Handy Andy automatically applies serial numbering, date codes, job numbers, lot numbers, and even company logos.

The recently released Handy Andy X version features:

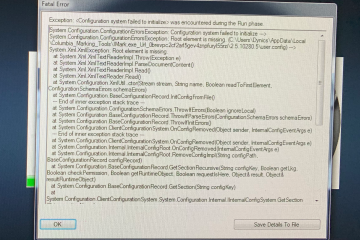

- updated software with an with intuitive control designed to run on any version of Windows®

- an increased marking window to 50x80mm

- a rugged and robust 5-wall heavy duty system frame, redesigned stand and mount

- upgraded speed and positional accuracy with new hybrid lead screw motor

- upgraded precision stepper motor linear actuators

- an advanced drive system with redesigned X and Y axis assemblies

- a new circuit board designed in-house with easy to replace components for rapid repair

- ease of operation designed to minimize training time

The Handy Andy X’s vibrating carbide pin impacts the material with up to 700psi (80N). The pin is able to mark flat or slightly curved surfaces. The marking window is 3.15” x 1.97” (50 x 80mm). Vertical height adjustment of the pin is up to 10.75 in. over the table.

To provide an entry point into automated marking, the Handy Andy X marking unit and software is marketed at about half the cost of most lower-end conventional programmable marking machines.

If you have further questions or would like a quotation, please give us a call at 586-949-8400. Or e-mail quotes@columbiamt.com.