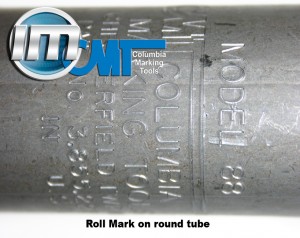

Case Study: 4 Line Roll Mark on Tube

Overview:

This case study highlights the use of the 860 all-air roll marking machine for marking heavy-duty steel tubes. The objective was to achieve clear, durable markings across multiple lines, ensuring long-term traceability and identification.

Project Details:

Part: Heavy Duty Tube

Material: Steel

Character Size: 1/8″, 3/32″ with Logo

Number of Characters: 4 lines of variable information

Marking Method: Roll Marking

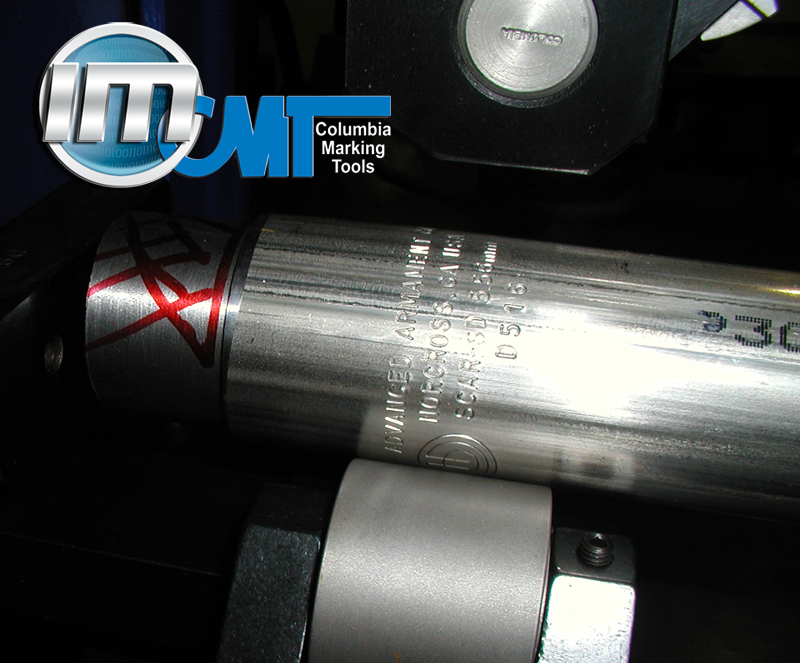

Machine Used: 860 All-Air Roll Marking Machine with A61 Cylinder (6100 lb)

Air Pressure: 60 psi

Cycle Time: 2 seconds

Note: A roll cradle was used to support the part. A custom die with multiple lines of text was used to ensure precision and consistency in marking.

Challenges:

Ensuring deep, legible marks on heavy-duty steel tubes.

Stabilizing the tube during marking to prevent misalignment.

Applying sufficient force for consistent marking across all four lines.

Solution:

The 860 all-air roll marking machine with an A61 cylinder (6100 lb) was selected for its ability to apply extra force necessary for clear and consistent multiple-line markings. A roll cradle was incorporated to stabilize the tube during the marking process, preventing movement and ensuring accurate placement. A custom die was utilized to imprint text and logos precisely as required.

Results:

Strong, clear, and permanent marks on heavy-duty steel tubes.

Increased efficiency with a quick 2-second marking cycle.

Stability ensured with a roll cradle, reducing errors.

Reliable identification and traceability for industrial applications.

Conclusion:

The 860 all-air roll marking machine provided a highly effective solution for marking heavy-duty steel tubes. With its high-force capability and precision-engineered design, it ensured durable, high-quality markings while maintaining production efficiency.