Roll Machine ( AG05534 & AG06363 )

960-AG1000 Automated disc brake diamter to diameter roll marking machine

A. All steel fabricated heavy duty floor style machine base with leveling feet

B. All steel machine structure attached to base

C. Powered roller conveyor for part transfer

D. Attaching points for Asama upstream and downstrean automation – Machine length 5′

E. High and low level switches for part flow

F. Pneumatic powered part location stops with part present detection

G. Pneumatic powered part escapement

H. Turnkey complete marking station to process one disc per machine cycle

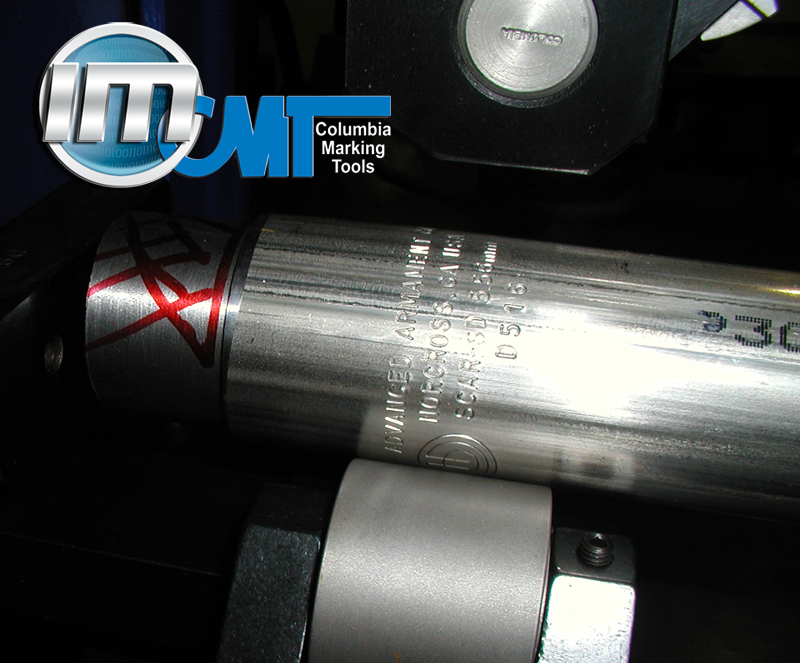

I. 960R-A43-40-R2S2

J. Independent CMT exclusive seek and find pressure ram

K. 2″ adjustable tool to part setup

L. Severe duty rated “Rotary Drive” allows for increased

marking length capacity. 11.5″ maximum mark length.

M. Ram and slide position switches

N. Keyed all steel machine frame with (4) bolt mounting

O. Component design for serviceability

P. Heavy duty cam follower bearings

Q. Ampco bronze heavy duty press ram bearing guide

R. All necessary SMC pneumatic control valves mounted and piped

S. OSHA required air shutoff valve

T. Air inline coalescent filtration and system pressure regulator

U. Machine completely assembled, painted and crated for truck shipment

V. Roll cradle support and drop in spacers for various diameter rotors

W. Paint spec is Sherman Williams Osha Blue (4086)