MODEL 860FM

- Chromolux Roll Marker fig 1

Columbia Marking Tools has been designing and building roll marking machinery for nearly

50 years. The technology still remains very popular today because a rolling die

has a relatively small point of contact with the part surface to be marked, so

it can be used effectively on tubular and thin-walled types of parts. The

adjustable marking pressure is only a fraction of the pressure that is

typically required by impact or press marking, and the marking speed is far

greater than that of peen or laser markers.

One of the leading industrial heater manufacturers recently purchased a Model 860FM stand-alone, all air-powered,

roll marking machine from Columbia Marking Tools to mark up to forty-eight

1/16-inch characters along the length of various diameter heater tube elements.

Tube diameters are .260, .315 and .475-inches, in lengths from 20 to

144-inches. Tube wall thickness is either .028 or .032-inches. Tubing material

includes stainless steel, Incoloy™ and copper.

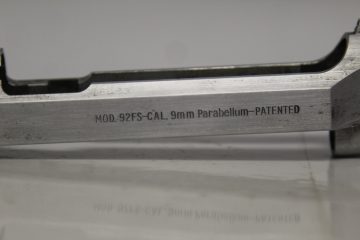

The basic design of the machine, Fig. 1, includes a heavy-duty steel weldment base

to which the Standard Model 860 A22 roll marking unit is bolted. This unit has

a minimum marking pressure of 565-lbs and a maximum of 2260-lbs. The unit

features a cast iron framework to which is mounted the 2-inch stroke air-ram

cylinder; a 3-1/2-inch adjustable internal die slide that provides the rolling

action for the round marking tool; and a cast iron, T-slotted, adjustable table

for mounting the various tube fixtures. Fig. 2. the tube manufacturer provided

the outrigger supports for the various tube lengths. Dovetail quick-change (30

seconds or less) tooling is provided for the different roll marking assemblies.

The machine also includes dual, anti-tie down, anti-repeat palm buttons, and a

complete plug-and-play air system package that includes filter, regulator,

pressure gage, lubricator and shut-off/lockout valve.

Depth of marks range from .003 to .008-inches depending on the material being marked.

Production rate for tube elements is 1000 per day. The machine is capable of

marking 600 parts per hour.

CMT Maquinas Marcadoras is a leading designer and manufacturer of metal and plastic

marking equipment including stamps, roll marking dies, roll marking and impact

marking machines, fully programmable laser, peen/scribe marking and UID/2D

Square ◙ Dot® machines, numbering heads and special marking machines. CMT is

working with HEMSA Herramientos Eclusivas y Maquinaria SA de CV, Maiano Azuela

No 194, Col. Sta. Ma La Riberia, C.P. 06400, Mexico D.F. www.hemsa.com.mx . For more information,

visit www.maquinas-marcadoras.com.mx