PULSED FIBER DIODE LASERS SPECIFICALLY DESIGNED FOR MARKING

MARKING TOOLS INTRODUCES NEW 10 AND 20 WATT

COLUMBIA

PULSED FIBER DIODE LASERS SPECIFICALLY DESIGNED FOR MARKING

Pulsed fiber lasers have become the preferred laser technology for identification and traceability marks for metals and plastics when their application has been determined to be either the most cost-effective, produce marks that are the most readable or integrated most easily with production operations.

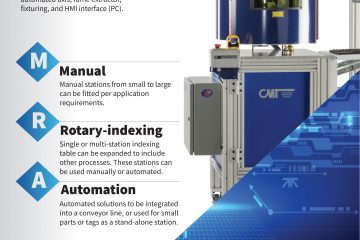

Tom Phipps, CEO of Columbia Marking Tools, says, “The laser has merely added another method of marking technology to the list of processes available to manufacturers today. As marking experts, we pride ourselves in having the best marking technologies available to our customers which include hand stamping, impact marking, roll marking, peen or scribe marking and now pulsed fiber diode laser marking.”

Phipps explains, “The key to providing the best marking solution is ultimately determined by a myriad of factors. One type of marking process is not the answer for every application. For example, what type of mark is required? How big does the mark need to be? How deep does it need to be imprinted? What kind of material is being marked? Has it been heat treated? Is the marking process part of the manufacturing process, or is it performed off line? In some instances, laser marking may be the best method, and Columbia has a unique

new laser marking system to do that.”

NEW PRODUCT RELEASE ON NEW COLUMBIA LASER MARKERS…/2

The new Columbia 10 and 20 watt laser marking systems utilize pulsed laser technology that develops the same 1064mm wavelength as Nd:YAG and Nd:YVO4 but are very compact in design, Fig. 1, and completely air-cooled so costly water cooling systems are not required. The airflow is segregated from any electronic components, so no filters require changing and component life is maximized. Because the pulsed fiber laser uses a doped fiber technology, sensitive optical components are eliminated which makes them ideal for industrial integration. The pulsed laser offers 90% useable power range compared to approximately 30% usable power range associated with YAG and YVO4 systems.

Columbia laser markers use proprietary software that enables the laser system to be tailored to the customer’s requirements with specific application for UID/2D marks. The software applies a standard Windows® user interface that reduces the learning curve for the technician. All standard marking functions include alpha numeric (linear & elliptical), bar codes, data matrix, UID (Unique Identification) and graphics, Fig. 2. Also, all laser parameters are saved with each marking object with numerous objects possible per mark. Part changeover is as easy as clicking on the next job to be marked.

Tom Phipps adds, “Providing laser marking integration services including system design and manufacture is what sets Columbia Marking Tools apart from other laser marking machine manufacturers.” Columbia provides total laser integration with respect to:

- Design and engineering of laser markers to fit the user’s specific marking needs including UID/2D marking with vision system verification

- Design and fabrication for regulation laser safety guarding

- Design and engineering for part fixturing or automation

The basic Columbia CMT laser marking system includes; a CMT laser marking head with a 163mm F-Thets focusing lens for a 100mm x100mm marking area, a CMT laser marking head controller box with a diode-pumped power source that is fiber coupled to the marking head; CMT proprietary software package. The base price of the package is $49,800.

NEW PRODUCT RELEASE ON NEW COLUMBIA LASER MARKERS…/3

There are also an array of optional items that include special guarding, air extractors,

Class I & II enclosures, training and installation.

Columbia Marking Tools is a leading designer and manufacturer of metal and plastic marking equipment including stamps, roll marking dies, roll marking and impact marking machines, fully programmable pulsed fiber diode laser, peen/scribe marking and UID/2D Square ◙ Dot® machines, numbering heads and special marking machines

Captions for Photographs

Fig. 1 (Photo No. CMT163A) – New Columbia lasers use pulsed laser fiber technology.

laser sources and controls are very compact enhancing

their integration into manufacturing systems.

Fig. 2 (Photo No. CMT163A) – Columbia laser markers can provide all standard marking

functions include alpha numeric (linear & elliptical), bar

codes, data matrix, UID (Unique Identification) and

graphics.