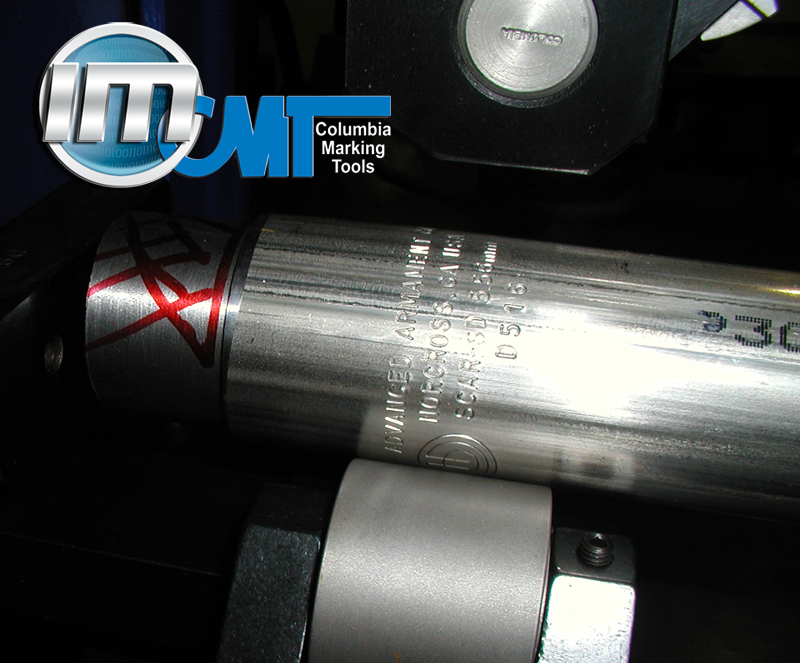

260 Roll Marking Machine

- 260 Roll Marking Machine

Project scope: CMT to supply two model 260 Roll Marking Machines. Customer to supply part fixturing. Marking legend is typically 6-8 (1/8″) characters and the Customers Logo, estimated marking time is 3 seconds. Parts are threading inserts that will be marked on the flat top side of the parts.

Note: machine to have CUSTOM BASE with height of 38″ from floor to part fixture mounting surface. Also to have CUSTOM PALM BUTTON arrangement with horizontal mounting of buttons to column (not base), these buttons are to have special LOW PRESSURE push settings.

3 different part fixture drawings were provided to CMT:

– EJ727 sheet #5 is a riser plate of some kind with a height of 3.125 inches

– EJ727 sheet #4 is an adapter plate of some kind with a height of .750 inches

– J23867 sheets #1-#6 are insert holder fixtures that range in height from 1.0 inches to 2.2 inches with a mean height of 1.6 inches.

Based on the provided drawings CMT will use the combined height of all three part fixture details of 5.4″ from our table mount surface to achieve the 38″ height from floor as stipulated in the above note. CMT will send approval drawing for customer signoff showing this height, signing the drawings means that you have approved this fixture stackup calculation as being correct or representative of the typical fixture height that you will use.

260AF01238 – 260FM-A43-20-R9S9 All air powered roll marking machine including:

a) CUSTOM Heavy duty, all steel, floor style, machine base with 38″ height from floor to top of table (fixture mount)

b) 2″ maximum ram stroke

c) 6″ maximum adjustable die slide stroke

d) CUSTOM OSHA approved dual anti-tie down, anti-repeat palm buttons and ring guards TO BE MOUNTED TO COLUMN in horizontal mount with buttons facing operator. Also to feature LIGHT PRESURE button / valving to make for easier mark start initiation.

e) Pressure “seek & find” marking system 4,300# max pressure

f) Optional ram regulator system (allows control of mark depth while maintaining system pressure)

g) Air inline OSHA approved lockout shutoff valve, filter, regulatror, pressure guage and lubricator

ih Quick change dovetail tool mount

i)Painted machine enamel blue

Engineering and Design Package including:

a) ACAD drawing format

b) Machine layout assembly

c) Tooling layout

d) Component stocklist

e) Air circuit diagram

f) Sequence of events

g) Approval drawings

h) Wiring diagram