Laser Marking Machine With Rotating Index Table Inclosed

- Full Machine

- Enclosure2

- Enclosure3

- Enclosure4

- Fixtue

- Fixtue With Part

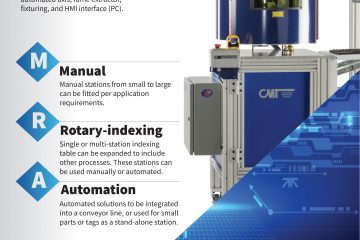

Project Scope:

CMT is to provide a Fiber Laser machine to mark aircraft retainer assemblies with UID code

1.Part is aircraft retainer assy

2.Material is 8620, 4340, 4140

3.Marking legend for part # CL40093-7-23 is: contains 2 UID codes first one to contain construct 1 and second one to obtain part number, part also contains manreadable charcters, using Mill Std 130 aircraft standard

4.Marking legend for all other parts to be alpha/numeric. (please provide prints on all parts with marking legends and locations).

5.Data to be manually entered

5.Mark time: around 60 seconds

6.Part loading: manual

7.Rotary index table provided for gang marking of up to 4 parts, not for marking on diameter of part.

8.Laser marker must be able to have height adjustment that allows for marking parts 12″ tall from face of rotary index table.

CMT 20 Watt Pulsed Fiber Laser AD03010 Marking Machine including

1. 1064nm wave length pulsed Ytterbium laser source

a. Pulsed Ytterbium fiber lasers boast at least five times the laser life source (50,000 – 100,000 hours), Nd:YAG or ND: YVO4 laser are (10,000 – 20,000 hours maximum)

b. Our wattage rating is based on average power at the point of marking. This is roughly equivalent to a 40-50 watt continuous wave Nd: YAG or Nd: YVO4 unit.

2. NEMA enclosure for adverse / industrial environment with operating lights & emergency stop

3. System and software manuals

Industrial Laser Marking Head including:

1. High speed galvanometer beam control

2. 160mm F-theta focusing lens for a 100 x 100mm marking area

3. Lightweight design and easy mounting features enables marking in any orientation

4. 3 meter standard cable to controller (longer lengths can be purchased)

CMT Custom Marking Software featuring:

1. Windows based software with extremely easy operator interface

a. Including drag and drop features for text, graphics, barcodes, circles and lines

2. The software also features:

a. A red diode tracing feature which displays an outline box for graphics and true trace for text enabling precise marking legend placement onto part prior to actually marking the part

b. The ability to save part files complete with all marking parameters

3. Optimized for pulsed fiber laser use

a. Fastest pulsed laser marking system available

b. Faster cycle times than comparable Nd:YAG and Nd: YVO4 systems

4. Software uses the Windows found folder for text objects and marks any true-type font

5. Full serialization, includes placeholders and fixed data prefix/suffix. Standard for all text and barcode / data matrix objects

6. UID compliant

Laser AD03010 Marking machine base:

1. Heavy duty base with casters

2. Marker head assy with power Z axis height adjustment up to 12″ tall (see option)

3. Class 1 laser manual open and close enclosure with easy open front door with integrated cycle interrupt safety switch

4. Exterior side mount tray for 15″ flat screen, keyboard & mouse

5. Operator E-stop & cycle start button panel on front of machine

6. Work light

7. Integrated with Programmable (up to 4 positions) 12″ rotary index table for 50lbs max weight (all parts)

8. Standard marking window is 4″ x 4″

9. Standard PC controller with 15″ flat screen monitor, keyboard & mouse

10. All components fully integrated into CMT base and tested

11. Cognex Vision system to read / verify UID codes

a. Cognex software preloaded and configured onto PC for UID marking

b. Power supply, light source, cables, I/O module, lens

c. Mounting bracketry and hardware to integrate camera into CMT base