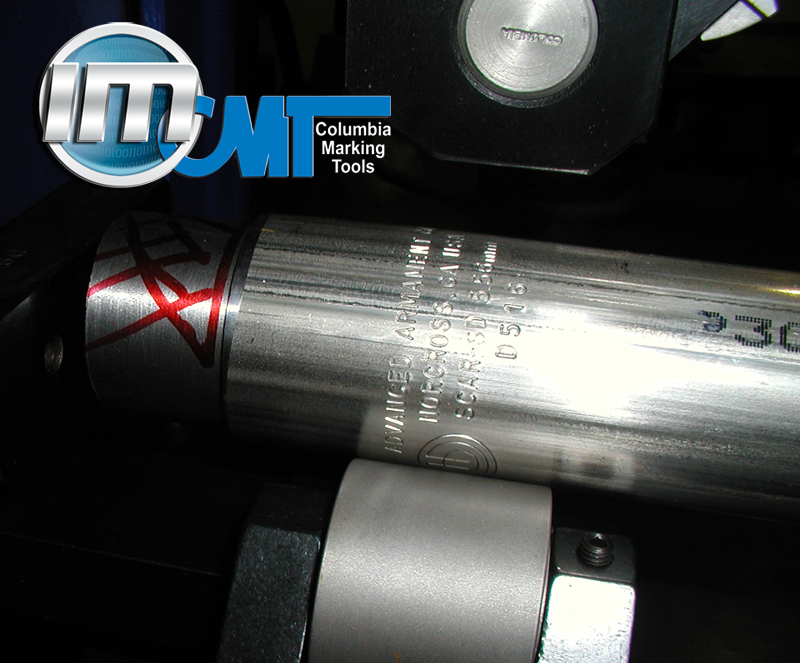

Roll Marking Machine

- Machine Back

- Part in Fixture

- Side View Machine

- Whole Machine

Project Scope: CMT to provide air powered roll floor style roll marking machine with part handling for customer integration.

Part: large steel bearing

Material: AISI 8720

Cycle time: 20 seconds (without conveyor information CMT can not project exact time)

Marking legend will consist of 35-40 characters, the mark will incorporate stamp dies and numbering head.

CMT to provide complete roll marking station:

*Marking machine

*Custom frame and floor base

*All required controls for automated and manual mode

*Custom master fixture plate for automated loading and unloading

*Automated mandrel with 3 different support mandrels (or versatile design to accommodate part differences). *CMT to provide support mandrels for three different part sizes: diameters range from 5.9″ to 6.325″

*Safety Guarding

*Numbering head

*Steel Stamps

*Operations and Maintenance Manuals: 1 page Easy operation sheet laminated and to be pinned to machine, complete operation guide and maintenance manuals electronically provided

Options:

*HMI interface with dual language (English/Russian)

*Digital Counter with Password protection (English only)

*2 year warranty

Customer responsible for:

Machine will be auto load and unload (to be integrated by customer)

Material handling for unloading of parts. This includes:

1) Provide conveyor

2) Provide upstream part stop & valving

3) Provide upstream part sensor

4) Provide downstream part sensor

Marking legend will consist of 35-40 characters, the mark will incorporate stamp dies and numbering head. Character Size = 1/8″

260FM-A61-20-R4S4-AE06074 Heavy duty roll marking machine including:

a. Heavy duty floor style machine base

b. 6300 lbs maximum force at 80 psi

c. 6″ max adjustable die slide stroke

d. 2″ stamp to part ram stroke

e. Quick change dovetail tool mount

f. Custom master fixture plate for automated loading and unloading

g. Automated mandrel with 3 different support mandrels (or versatile design to accommodate part differences). CMT to provide support mandrels for three different part sizes: diameters range from 5.9″ to 6.325″

h. OSHA required Safety Guarding with interlock switch

i. Air inline particle filter, pressure regulator, pressure gauge, and lubricator

j. Optional mark depth adjustment with separate ram pressure regulator

k. Ram returned and extended position sensors

l. Slide (mark length) adjustable position sensors

m. Step down transformer for operation in Russia (380V/3 phase/50Hz)*

n. All required controls for automated and manual mode

m. Painted machine enamel blue

*all control voltage to be 24v