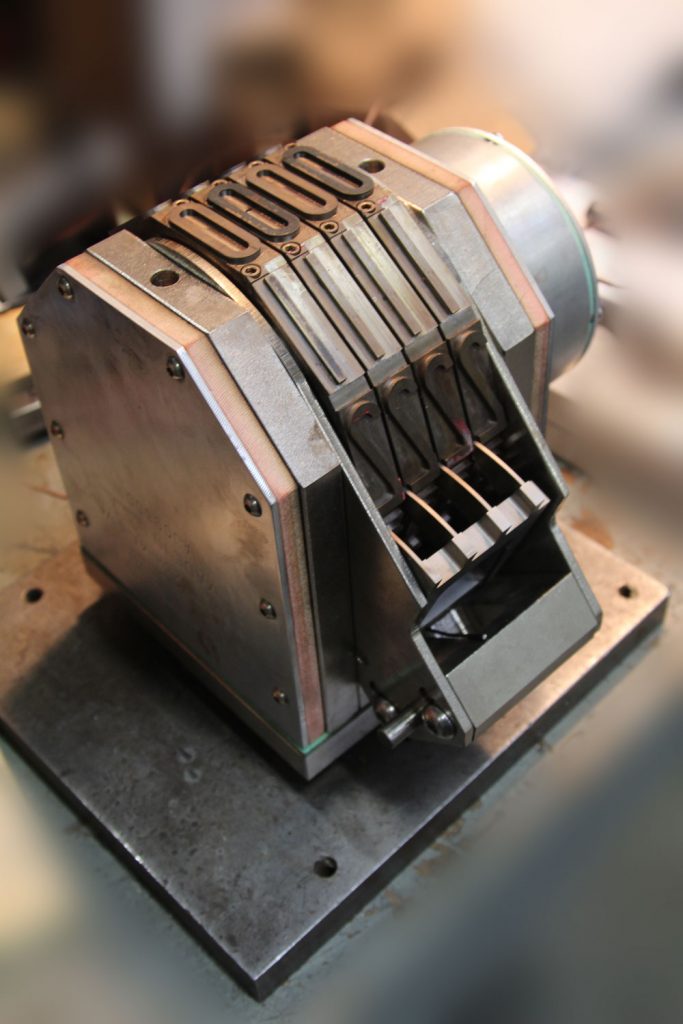

Hot Stamping Automated Numbering Head

Hot stamping provides a permanent mark on plastic materials. It uses both pressure and heat to melt and embed characters deep into the material’s substrate.

Why use this technique?

The first and most obvious reason is cost. Hot stamping can provide a deep impression in fractions of the time of other processes. This is especially important on high production plastic components where fractions of a second are life or death of a company.

In this example (4) 1 3/4″ characters are imprinted in less than 2 seconds, and more than .030″ deep into the plastic substrate. This numbering head also indexes to the next number automatically for the next mark.

CMT has developed a special technique to heat the large surfaces to an even temperature. Many hot stamping operations fail due to the uneven heating of the marking surface. The J Wire thermo-couple can be control via a PLC or other heat control system. This system can be used at up to 800 degrees Fahrenheit.

The CMT patented pawl system allows for exact positioning of each character. The precision engraved bronze wheels have removable zeros.