RE: Test marking date/ shift code with a 2D Data Matrix.

Thank you for providing CMT the opportunity to show you the new Square-Dot technology. This technology was developed to save customers money and provide them with a viable alternative solution to the expensive laser in marking 2D codes.

CMT and other dot-peen manufacturers are well aware of the limitation of the dot-peen technology to provide a reliable 2D machine readable code. The marks are round dimples and when the light refracts the surfaces the camera is unable to pick up the required “squares” to form the code.

We understand that you are experiencing this limitation of the dot-peen technology.

The following pages cover our test mark of your sample piece and a comparison with the provided mark already in production. And most importantly we also explain the technology of the Square-Dot behind the successful test.

Pin stamp Mark

Model: TMP1700 pin stamp

Marking: Transmission Cover

Material: Aluminum Casting

Characters: 1/8” characters

Reading: Date code/shift code. Serial number. Pin stamp Data Matrix

120815(sp)1(sp) 000

Cycle time: unknown

PSI: unknown

Mark location: Side of the transmission cover

Reading of Code that was rejected . – please note the rounded shape is limiting the ability of the mark to “fill” the cells.

Square – Dot Test Mark

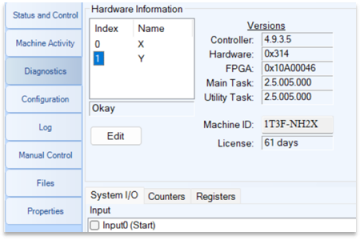

Model: IMIS60 Integrator Ballscrew driven scribe marking system

Marking: Transmission Cover

Material: Aluminum Casting

Characters: 1/8” characters

Reading: Date code/shift code. Serial number. With a 2D Square Dot Data Matrix

120815(sp)1(sp) 000 Square Dot

Cycle time: 53 Seconds

PSI: 30 PSI

Mark location: Side of the transmission cover.

.