I-Mark IMIS60 Square Dot Test Mark

Square – Dot Test Mark

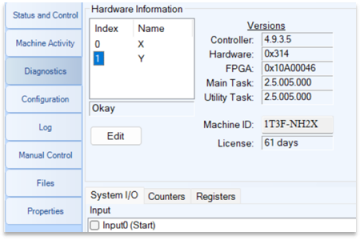

Model: IMIS60 Integrator Ballscrew driven scribe marking system

Marking: Transmission Cover

Material: Aluminum Casting

Characters: 1/8” characters

Reading: Date code/shift code. Serial number. With a 2D Square Dot Data Matrix

120815(sp)1(sp) 000 Square Dot

Cycle time: 53 Seconds

PSI: 30 PSI

Mark location: Side of the transmission cover.

( Full Layout) (Square Dot)

After the test mark was completed we performed a verification test and results are below.

Pinstamp Mark

Model: TMP1700 pinstamp

Marking: Transmission Cover

Material: Aluminum Casting

Characters: 1/8” characters

Reading: Date code/shift code. Serial number. Pinstamp Data Matrix

120815(sp)1(sp) 000

Cycle time: unknown

PSI: unknown

Mark location: Side of the transmission cover

Reading of Code that was rejected .

– please note the rounded shape is limiting the ability of the mark to “fill” the cells.

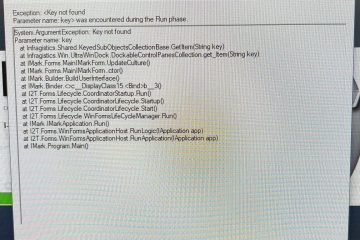

The Reason:

CMT’s patented high resolution marking process to apply 2D/UID machine readable

codes to a variety of materials. This process scribes a matrix of small square cells into the

material. The mark provides the best direct part reading with a vision system as the cells are

filled in similar to a laser mark but much deeper and often with better contrast

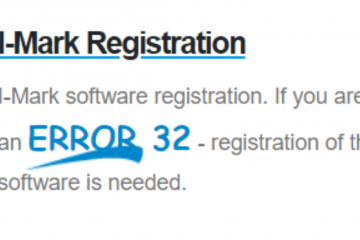

The Square-Dot® process may be implemented with any of CMT’S I-Mark Scribe systems,

these include I-Series air Scribe & the C-Series electric or air scribe.

The Square-Dot® patented process uses a diamond tip to draw squares on material to create a machine readable 2D/UID code. This technique creates both a depressed square and a raised ridge as shown below. The “filled cel” reflections create a more defined matrix as shown above, and therefore, offers better readability.

“..and all other dot peen markers imprint a round dot; whereas a laser marker is capable of marking a square cell. This adds to the relative readability of laser marks in 2-D applications, since a theoretically perfect Data Matrix® 2-D code is based on square cells.”

-Dot-Peen Manufacturer of failed Honda Mark